Employment

Equal Opportunity Employer

Employment

Equal Opportunity Employer

To the naked eye

Infrared imaging camera showing a heavy load on two breakers

To the naked eye

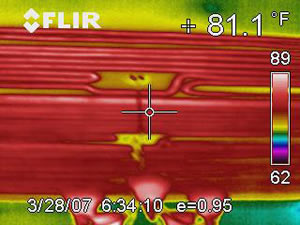

Infrared imaging camera showing existing ceiling heat

Thermography is the use of an infrared imaging and measurement camera to "see" and "measure" thermal energy emitted from an object. Thermal, or infrared energy, is light that is not visible because its wavelength is too long to be detected by the human eye; it's the part of the electromagnetic spectrum that we perceive as heat. Unlike visible light, in the infrared world, everything with a temperature above absolute zero emits heat. Even very cold objects, like ice cubes, emit infrared. The higher the object's temperature, the greater the infrared radiation emitted. Infrared allows us to see what our eyes cannot.

Infrared thermography cameras produce images of invisible infrared or "heat" radiation and provide precise non-contact temperature measurement capabilities. Nearly everything gets hot before it fails, making infrared cameras extremely cost-effective, valuable diagnostic tools in many diverse applications. And as industry strives to improve manufacturing efficiencies, manage energy, improve product quality, and enhance worker safety, new applications for infrared cameras continually emerge.

The most powerful and cost effective preventative maintenance tool available!

Infrared electrical systems inspections are typically conducted on an annual basis as part of a regular preventative maintenance program. A large amount of equipment can be inspected in a short time as opposed to the other method of physically inspecting and tightening components. The infrared inspection locates faulty items not generally found during a physical inspection, such as failing componenets, poor electrical connections and load imbalances. When hot spots and problem areas are located with thermal inspections, these areas can be repaired with planned shutdowns on your schedule, not as emergency repairs that can't be controlled.

Infrared surveys performed by our experienced thermographers provide a significant advantage to your preventative maintenance programs. It is inevitable that equipment failures and breakdowns will occur and there is no way to predict the extent of damage. Equipment failures often have financial consequences that go well beyond fixing the damaged component. In many cases, production downtime can far outweigh the cost of the repair.

Infrared inspection programs have proven that on the average for every $1 spent on infrared electrical inspections, there is a $4 return on investment for materials and labor from fixing the problem before it fails. In these days of just-in-time supplied parts, the inability to make good on a commitment can result in the loss of future sales.

By choosing to use Buschur Electric as part of your preventative maintenance program, you can get the upper hand on problems before they become emergency shutdowns and cause major expense.

We currently have two Level I thermographers on staff and all electricians are safety trained in OSHA and NFPA 70E.

Call 800.287.2487 today to schedule an infrared inspection as a part of your preventative maintenance program. In most cases you'll save more than the cost of the service.